auxiell Dojo: the real Lean experience from Japan in your company

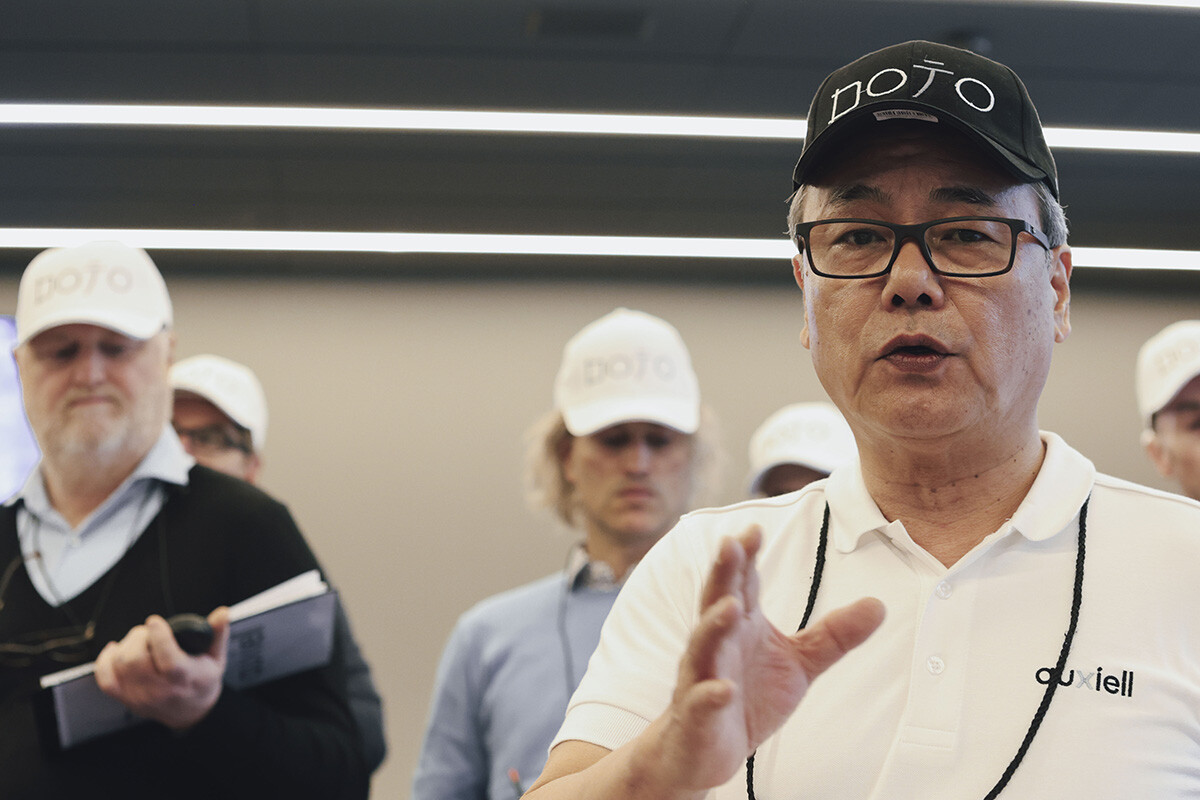

Dojo is a one-day training event designed to discover the secrets of process efficiency led by the Toyota Old Boys, former Toyota managers, team leaders and trainers with 40 years' experience in the company where what is known in the western world as the lean system was developed.

Specialised in training and spreading kaizen culture, the Toyota Old Boys passionately share what they have learned throughout their long careers. They are accompanied by an expert in Japanese culture, who acts as an interpreter and translator, and supported methodologically by an auxiell lean expert.

This initiative blends theory and practice, catering to various company profiles from managers to more operational roles, enabling participants to immediately apply their new knowledge in their own companies.

Programme for the day

The day includes both classroom training and practical experience.

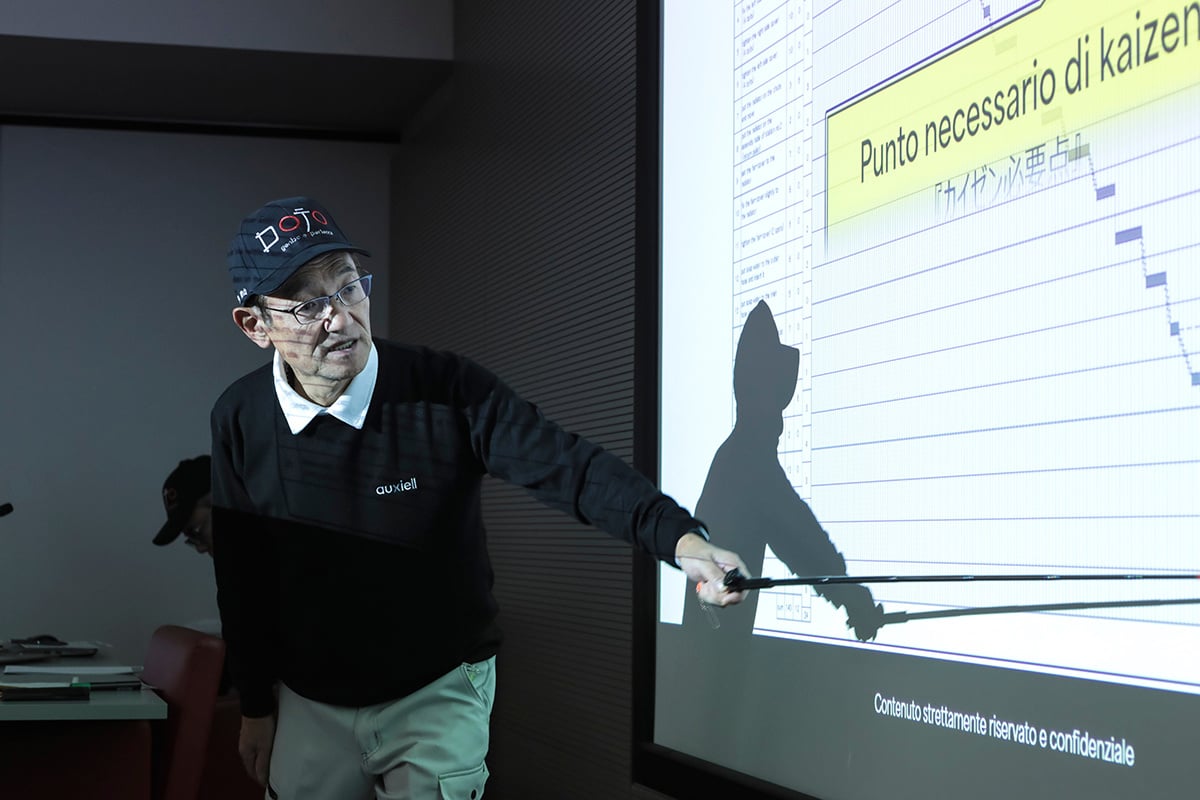

4 hours of theory

In the first part of the day, participants delve into the principles and techniques of the lean system, exploring its benefits and various applications under the guidance of a lean expert from the auxiell team.

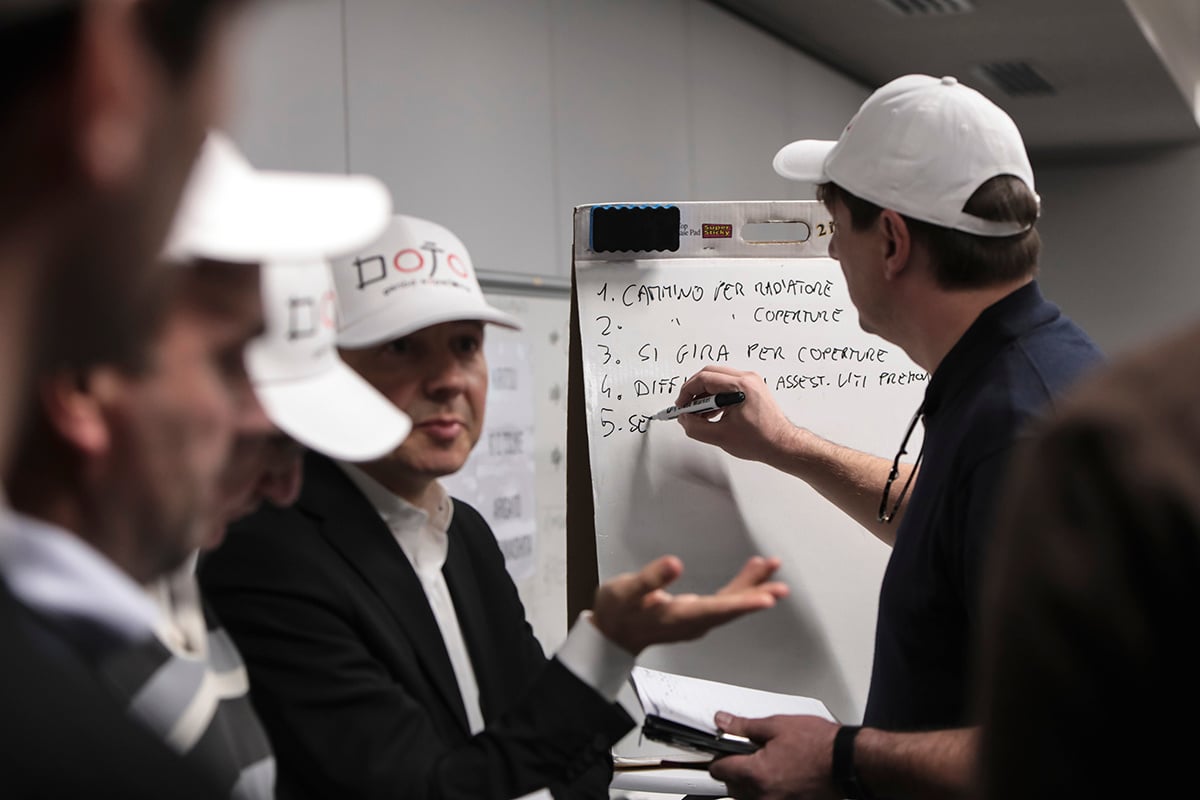

4-hour workshop

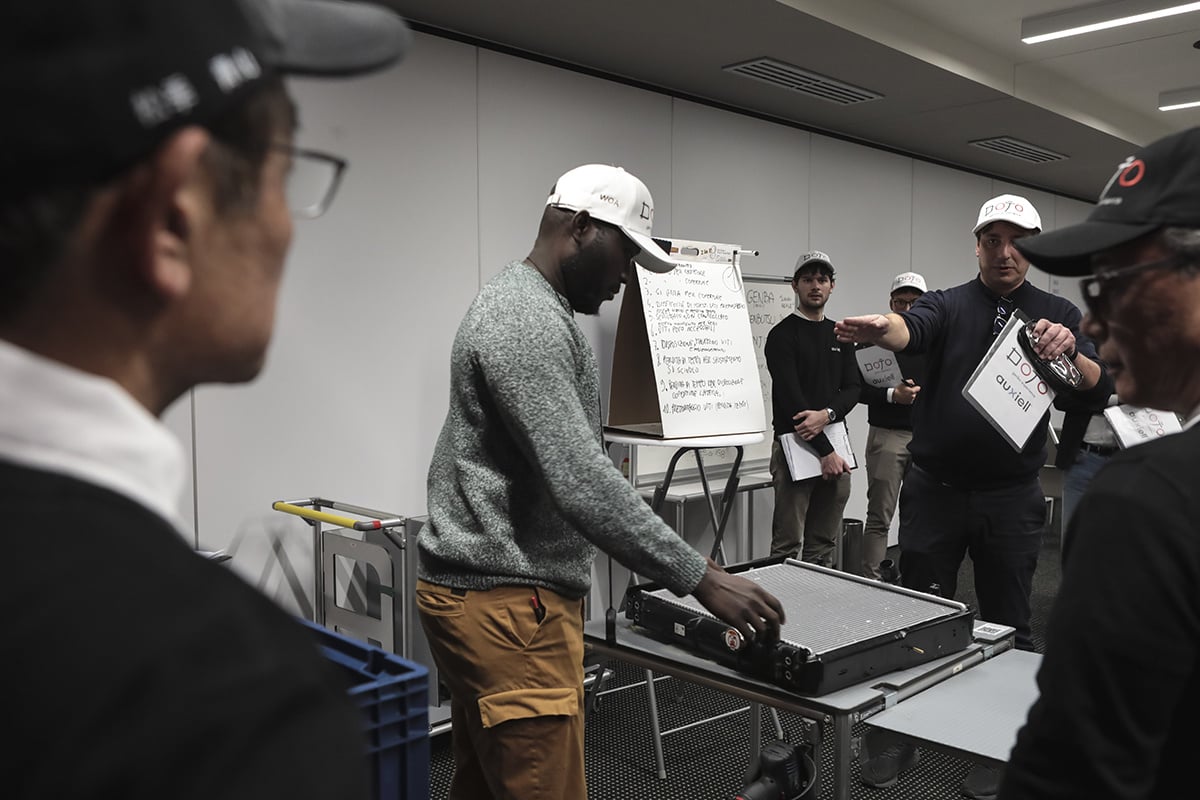

In the second part of the day, participants actively reorganise a production line to enhance its efficiency, applying the techniques learned during the morning session.

What does it take to organise a Dojo day?

Each day accommodates between 10 and 25 participants. Teams can come from a single company or multiple companies coordinating together. To organise a session at your company, you need a room large enough for the participants for the classroom training, and a second space, at least 8 x 9 metres, where the workshop equipment can be set up.

.jpg?width=2000&name=IMG_6230%20(2).jpg)

Our experts are available to support you with process transformation

Subscribe to our newsletter and receive exclusive content, practical tips, and updates delivered directly to your inbox!