Portfolio

S.P.F. Chilò

Intro

Lean enterprise objective: How embracing a culture of process efficiency has enhanced performance across the organisation

Industry

Headquarters

Performance Achieved

reduction in raw materials warehouse stock

semi-finished products inventory

lead time for the delivery process

(from order entry to final delivery)

reduction in tooling time

available production capacity

profit margins

conversion rate

Do you want to improve your company's performance?

Company

history

1965

Founded in 1965 by the Chilò brothers, SPF Chilò quickly gained a leading position in the sheet metal processing industry, specialising in the production of semi-finished products with significant dimensions and thicknesses. One of the first Italian companies in its production sector, in 1995 it obtained ISO 9002 certification, which has been maintained over the years, demonstrating its ongoing commitment to achieving high-quality standards.

Thanks to the high-quality standards achieved over the years, the company has built strong partnerships with both small businesses and multinational corporations. Today, it is a leader in the sheet metal processing and manufacturing sector, thanks to continuous technological development, the use of cutting-edge machinery and equipment, and investment in staff training for continuous improvement.

Employees

0Turnover

0EBITDA

0

The challenge faced by S.P.F. Chilò

Transforming the company into a lean enterprise by promoting a culture of change and waste elimination while ensuring business continuity through economic sustainability.

The starting point

The transformation of the first macro-process: Delivery

2020

Start of collaboration

with auxiell

continues

Con SPF Chilò abbiamo inizialmente intrapreso un progetto sul macro-processo di Delivery che comprende produzione, supply chain, gestione degli ordini e ufficio tecnico.

Dopo aver lavorato nel Delivery, con il team SPF Chilò abbiamo spostato il focus sul macro-processo di Demand che comprende vendita e gestione della domanda.

Dopo aver lavorato nell'efficientamento dei processi di Delivery e Demand, con il team SPF Chilò abbiamo intrapreso un progetto sul macro-processo di Deployment che comprende la traduzione delle strategie in attività coordinate tra loro.

SCAN

Lean Gap Analysis® in Delivery

To analyse the current state of the processes, the auxiell-SPF Chilò team carried out a Lean Gap Analysis® of the delivery process, which includes sheet metal cutting and cold forming.

Lean Gap Analysis®

An essential phase for measuring and analysing current processes and identifying the gaps between the present and desired states. During this phase, a 'snapshot' of the current state of processes is taken, focusing on quantifying waste, identifying potential problems and opportunities for improvement, and timing all steps. Gaining a clear understanding of process performance is crucial for determining the most effective countermeasures to eliminate the root cause of the issue, as well as for planning future actions and determining which KPIs to monitor to improve efficiency.

Stocks of raw materials between the technical department and the cutting phase

The initial focus was on purchasing material in stock with the aim of supplying it at the best possible purchase price, without considering its actual consumption. Furthermore, the material was not easily identifiable when needed, and the stocks of raw materials restricted the available work areas. Finally, the management of raw material scraps was out of control. These were becoming increasingly numerous and were stored in a large warehouse, making it difficult to identify them for use in production.

Overproduction

Some items were produced ahead of the actual date required by the customer, remaining in the warehouse for a prolonged period before being retrieved and processed. This was due to the organisation's initial focus on maximising machine utilisation and optimising raw material usage.

Waiting times due to a shortage of raw materials

Given the lack of coordination between requirements and purchasing, there were occasions when the necessary material was unavailable in the specific production phase at the required time.

Excessive movements of operators and material handling

The accumulation of semi-finished and finished products forced operators to constantly search for the material, resulting in unnecessary movement.

Incorrect processes: knowledge not utilised

The production planning process was heavily reliant on the experience of the personnel involved and was not standardised, leading to time wasted on low-value activities.

Waiting times due to information flow issues

Production suffered delays due to the lack of specific information regarding orders, which had to be retrieved from the sales team or technical department upon request.

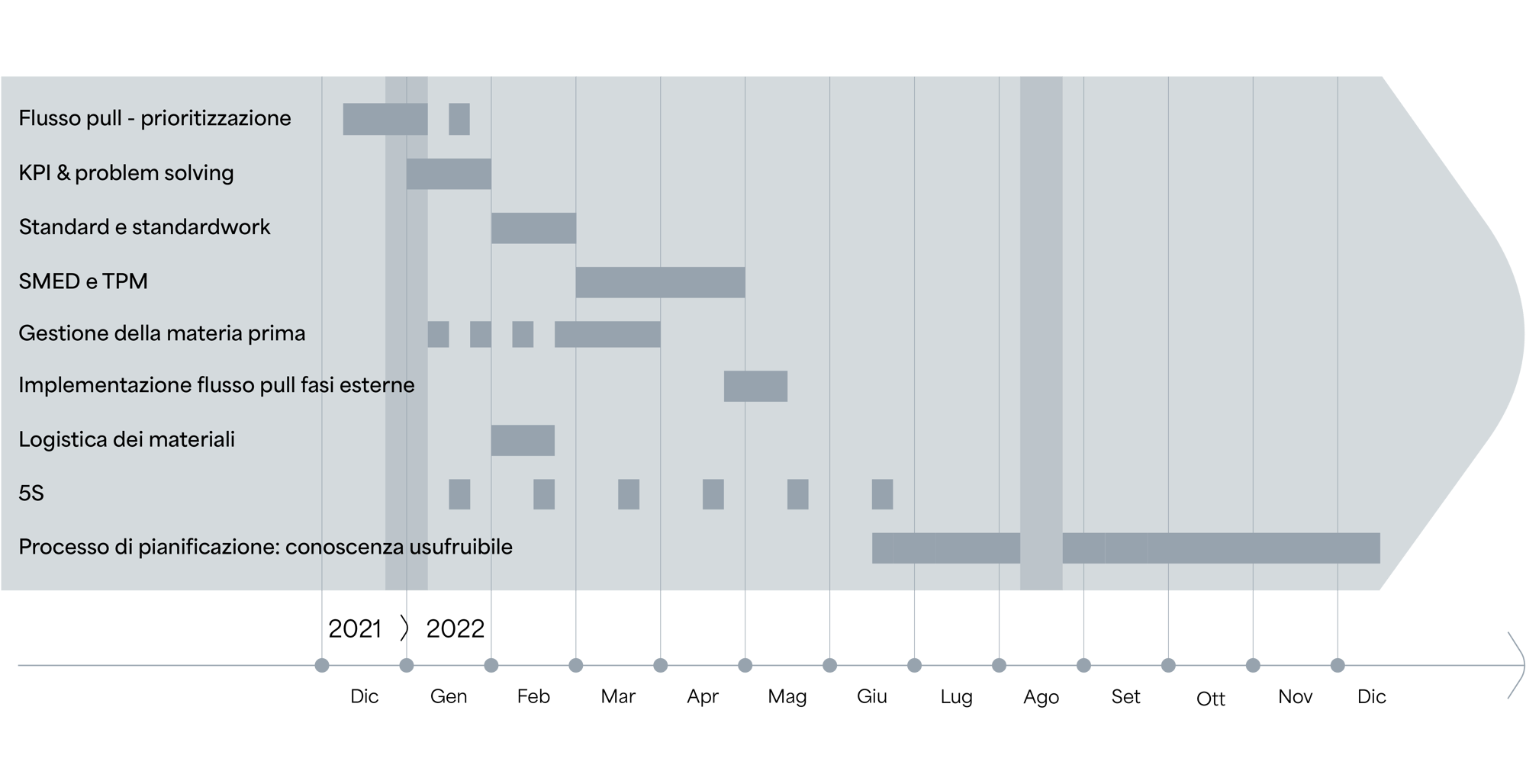

PLAN

Lean RoadMap® in Delivery

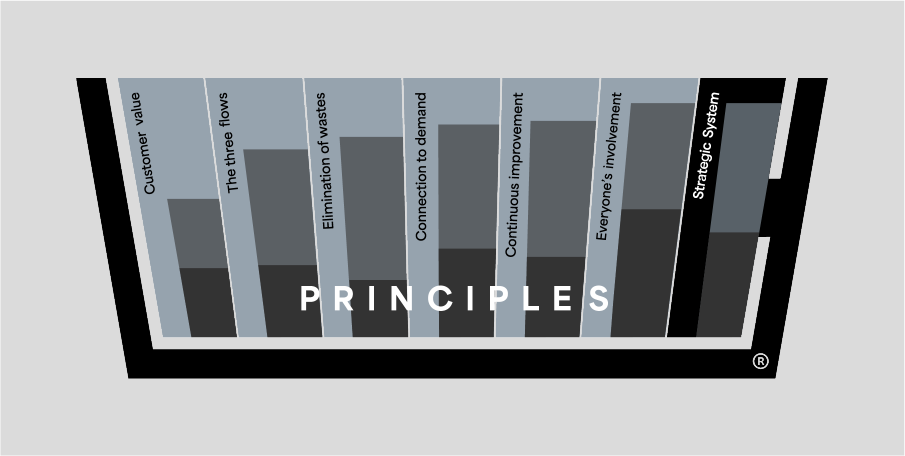

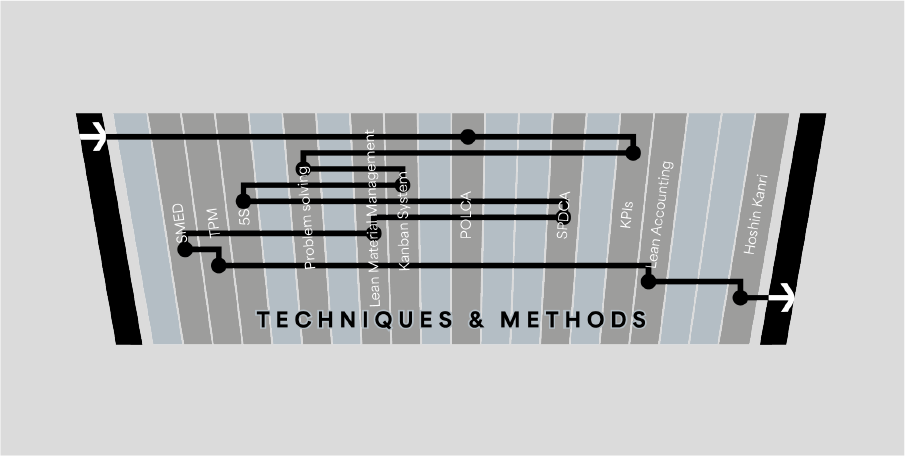

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the SPF Chilò team. The Lean RoadMap® outlines the techniques and methods applied throughout the project

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective. Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it. The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

Lean culture

To establish and promote a lean culture while improving indirect processes – focusing on both efficiency and effectiveness – through employee engagement and theoretical and practical training on lean system principles and techniques. People are the key to delivering results, and training enables them to become autonomous in optimising business processes.KPI & Problem Solving

After the theoretical training, a daily meeting was implemented – called HASAICHI – during which, in front of the problem solving board, decisions are made and problems are solved by involving all stakeholders in the de.livery process. For example, in 2024 alone, the application of the problem solving technique led to 216 reports being opened and 195 closed. Some operational KPIs are also displayed on the same board, including punctuality, raw material volumes, generated scraps, and processing waste, which help guide the decisions made by the team.

Pull flow

To reduce lead time and minimise semi-finished product inventory, the cutting and bending phases must be linked. By doing so, financial benefits can also be gained by reducing the capital tied up in fixed assets. The cutting phase was linked to the bending phase using the prioritiser to reduce the amount of semi-finished product left idle between the two stages.

Pull system for raw materials

To reduce tied-up capital in raw material stock – especially when it accounts for 70% of the finished product cost – it is essential to implement a pull system between suppliers and production. By reducing sheet metal inventory, working capital is freed up, and additional space can be allocated for higher-value activities, such as installing new machinery to enhance the factory’s production capacity.

5S

To establish a culture of order, cleanliness, and efficiency in workspaces – in this case, in a heavy carpentry workshop.

SMED

Reducing machine set-up time allows us to increase the number of setups (without altering production capacity), thus accelerating flow speed and reducing production lead times.

Internal logistics of materials + Relayout, management of semi-finished and finished products

The relayout and subsequent revision of the material flow, by reducing wasted movement and transport, enhances the benefits of the above-mentioned flow system.

Planning process: usable knowledge

The development of an algorithm enables the planning logic to be made accessible to all, in an objective manner. This algorithm, based on the characteristics of the ordered finished product, can estimate the required processing time and recommend the most suitable date and work centre. This helps streamline the planning process, which in recent years had become increasingly critical, burdensome, and reliant on the experience of the involved staff.

Vertical integration of production phases

Internalising some production stages that were historically outsourced, such as machining (e.g. calendering) and welding, enables us to expand the product range offered to customers while maintaining reduced and controlled lead times. Furthermore, this strategic decision contributes to an increase in the contribution margin of the products sold.

Standard training process for bending operators and the technical department

To improve the quality offered, speed up the resource onboarding process – in a highly artisanal operation – and make the knowledge that was previously held by only a few accessible to all.

DO

Delivery Overall Transformation

Which lean activities and techniques enabled us to achieve our goal?

Lean Training

- Introduction to the principles of lean thinking

- 5S technique

- Value Stream Mapping - Understanding the theory behind process mapping and applying the learned techniques within relevant departments (identifying muda and redesigning processes)

- Market response and scheduling models, pull system, KPIs, and continuous improvement miglioramento continuo.

KPI & Problem Solving

After the theoretical training, a daily meeting was implemented – called HASAICHI – during which, in front of the problem solving board, decisions are made and problems are solved by involving all stakeholders in the delivery process. For example, in 2024 alone, the application of the problem solving technique led to 216 reports being opened and 195 closed. Some operational KPIs are also displayed on the same board, including punctuality, raw material volumes, generated scraps, and processing waste, which help guide the decisions made by the team.

Pull flow

The production flow was reviewed from a pull perspective using a prioritisation system where a signal – a card – from the next phase (bending) calls for the previous phase (cutting). This ensures that semi-finished products are not overproduced, keeping the stock within the set limits, reducing waiting times, and increasing the flow speed.

Pull system for raw materials

Using the Kanban technique, a pull signal was created for issuing orders to raw material suppliers for fast-moving materials/codes. Meanwhile, the management of orders based on demand has been standardised for slow-moving materials (without stock), which are ordered specifically for each customer. All of this was made possible thanks to specific agreements with suppliers, enabling the establishment of a win-win process: the supplier, knowing the forecasted material consumption, can produce it when needed.

5S

A technique applied – and continuously evolving – both in production and in the offices, involving the entire company. The entire team participated in daily workshops to reorganise the entire plant.

SMED

The SMED technique was applied with the operators and team leaders of the bending department, aiming to reduce tooling times as much as possible. The technique was applied to two 8-metre-long presses of different sizes. All the necessary procedures and standards were then developed to allow the technique to be applied to the other presses in the machine fleet.

Relayout, management of semi-finished and finished products

By applying pull logic to raw materials and semi-finished products, the available space increased, creating an opportunity to review the layout, expand the machine fleet, and thus increase production capacity. By freeing up space, the material handling flows were also revised – standardising the input and output areas on each machine – and a dedicated area for managing scraps was created. These improvements contributed to the reduction of transport waste and time spent searching for materials.

Planning process: usable knowledge

The mental processes (experience) of those responsible for production planning were mapped, systematically quantifying all the variables involved and creating an algorithm capable of estimating processing times, identifying the most suitable production area, and determining the first available machine.

Vertical integration of production phases

Thanks to the recovery of space, it was possible to invest in verticalising the calendering, machining, and welding processes. These phases are now carried out internally, rather than externally, positively impacting lead times and profit margins.

Standard training process for bending operators and the technical department

The training process for the technical department and the team responsible for the bending phase has been revised to reduce lead time for the integration of new resources This new process includes periodic updates to standards as soon as indicators show deviations from the set target. This ensures the maintenance and continuous improvement of standards.

CHECK

Have we achieved our goals?

Thanks to the application of pull logic and continuous improvement, the raw materials inventory has been reduced by 53%.

The implementation of pull logic and the standards applied in production (which have radically changed people’s habits) resulted in a 60% reduction in the presence of semi-finished products.

The lead time of the delivery process – from order entry to delivery – has been reduced by 40%, thanks to the reduction of semi-finished goods and the elimination of waste in production.

Thanks to the SMED initiatives and the coordination of the operator's role, tooling times have been reduced by 35%.

Production capacity has increased by 42%. The space recovered from reducing inventory has allowed for more warehouse space, enabling the addition of new machinery, which in turn has positively affected production capacity, improved planning, and increased the machine fleet.

Usable knowledge has increased. Previously, all production planning was entrusted to a team that, based on customer drawings, manually created the time estimates required for production. Now, all the variables that were previously known only to the team have been made objective and correlated into an algorithm that, based on the characteristics of the required processing, automatically assigns the order to the appropriate machine and calculates the time needed for its completion.

The project carried out with the SPF Chilò team has achieved significant and tangible results. Through a targeted and collaborative approach, we successfully addressed initial challenges, generating a positive and lasting impact on the team. The success of this initial collaboration has laid the foundation for a mutually trusting relationship, which has already allowed us to explore new growth opportunities together.

From Delivery to Demand

After working in Delivery, together with the S.P.F. Chilò team we shifted the focus to the macro-process of Demand, which includes sales and demand management.

SCAN

Lean Gap Analysis® in Demand

To analyse the current state of the processes, the auxiell-SPF Chilò team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the sales process, involving the entire sales force and the complete product range in order to computerise and standardise the sales process, making it measurable and controllable.

Lean Gap Analysis®

An essential phase for measuring and analysing current processes and identifying the gaps between the present and desired states. During this phase, a 'snapshot' of the current state of processes is taken, focusing on quantifying waste, identifying potential problems and opportunities for improvement, and timing all steps. Gaining a clear understanding of process performance is crucial for determining the most effective countermeasures to eliminate the root cause of the issue, as well as for planning future actions and determining which KPIs to monitor to improve efficiency.

Overproduction of offers

Due to the lack of standards for creating sales offers, the sales team had various tools at their disposal for making quotations. However, the way these were communicated could either add value or not to the customer.

Lack of analysis and problem solving regarding the difference between estimated and final costs.

The sales team was making numerous quotations daily based on the offers received, without knowing which had higher priority or a greater chance of success.

PLAN

Lean RoadMap® in Demand

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the SPF Chilò team. The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective. Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it. The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

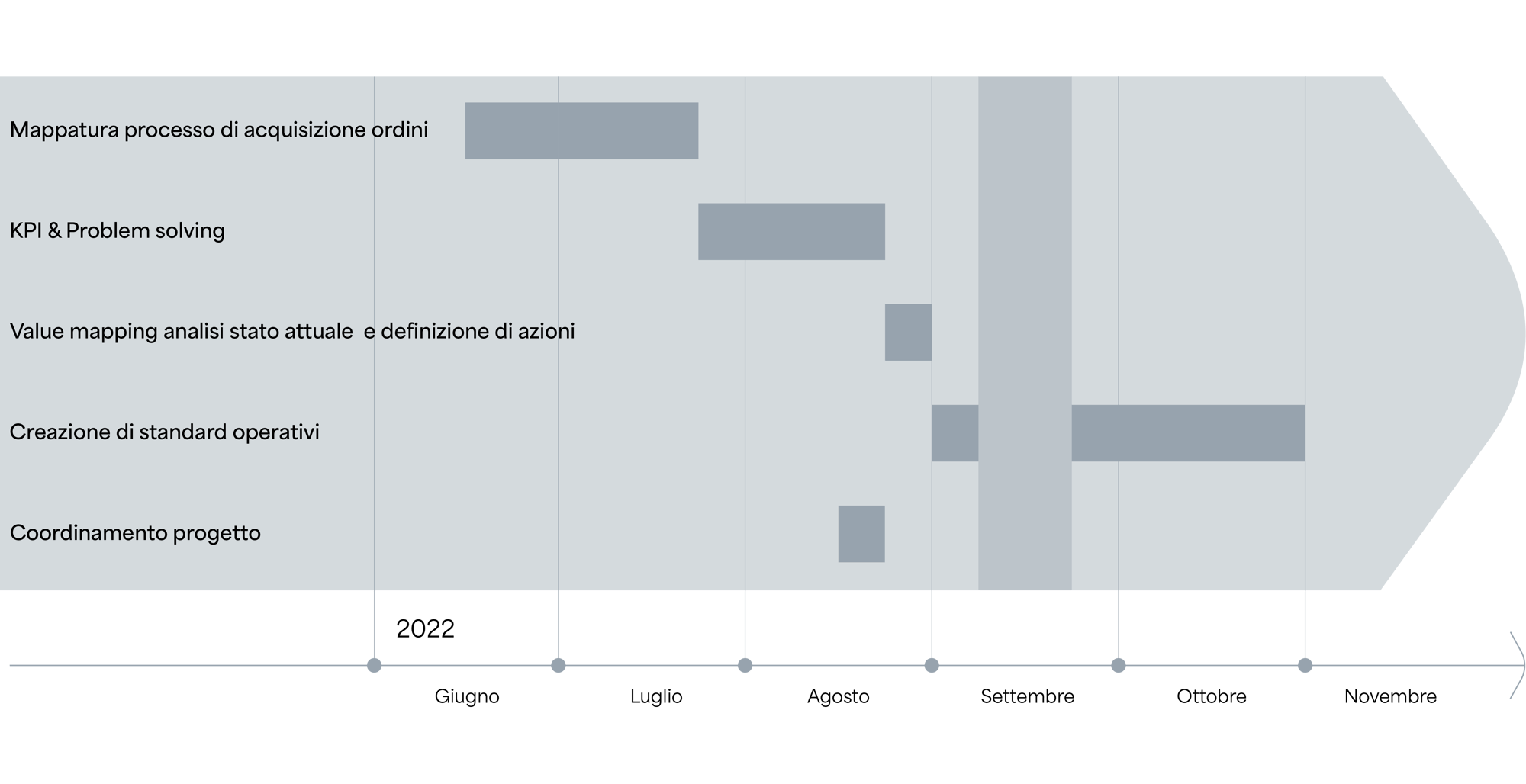

Mapping the order acquisition process (from receiving the offer to entering a sales order)

To assess the current state of the sales process in order to monitor and improve its efficiency. To achieve this goal, the first step was to standardise operating procedures and foster synergy within the team. ‘Less communication, but of higher quality’.Definitions of KPIs

To optimise the quotation process by identifying the most relevant performance metrics for decision-making.

Technical application of problem solving

To improve the conversion rate of offers into orders, lost offers were analysed to identify the determining factors and enhance the profit margins of acquired orders.

DO

Lean Sales & Value Selling

Which lean activities and techniques enabled us to achieve our goal?

Mapping of the order acquisition process (from receiving the offer to entering a sales order) and muda analysis

Using the Makigami technique, we mapped the process, specifying the sales team members involved and the timing of each phase. Using the Makigami technique, we mapped the process, specifying the sales team members involved and the timing of each phase. Through Muda Analysis, the root causes of waste were then determined using the 5 whys technique, leading to the identification of possible solutions for their elimination or reduction.

Creation of standard operating procedures

Relevant aspects were identified – such as customer loyalty, processing complexity, urgency of response to the customer, and the estimated amount – to quantify and prioritise the requests for quotations received. A second standard concerned the standardisation of the tools used by the sales team to prepare the quotations. Specifically, the number of tools used was reduced to two (from at least three previously), and a standard was defined for use cases. Finally, a planning tool was added to support the final costing tool for estimating the processing time – and therefore the costs – of requests for quotations.

Definitions of KPIs

The muda analysis revealed that most of the waste stemmed from the lack of process measurement, which would allow for monitoring and analysis. For instance, the following KPIs were introduced: average margin of acquired orders – distinguishing between orders resulting from offers and those that were not – and the conversion rate of offers into orders.

Technical application of Problem Solving

Weekly meetings were held between the sales team and the order entry team – as not all orders went through the offer process – to review the progress of performance metrics and ensure the achievement of the strategic objectives set for the month.

CHECK

Have we achieved our goals?

The conversion rate from offers to orders has increased by 10%.

Profit margins (under favourable market conditions) have increased, thanks to the work done on the demand process (especially around managing and quantifying offers).

From Demand to Deployment

The efficiency journey undertaken in Demand has once again paved the way for implementing the same continuous improvement practices that led to excellent results in the first three macro-processes where they were initially applied. The goal remains to fine-tune processes, reduce waste, and increase productivity, ensuring better alignment between demand and development, thereby maximising the overall effectiveness of the organisation. This creates the need to move to the strategic level in order to align and coordinate the entire organisation with a lean approach, focusing on the Deployment macro-process.

SCAN

Lean Gap Analysis® in Deploymnet

To analyse the current state of the processes, the auxiell-SPF Chilò team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the process of translating strategies into coordinated activities.

Lean Gap Analysis®

An essential phase for measuring and analysing current processes and identifying the gaps between the present and desired states. During this phase, a 'snapshot' of the current state of processes is taken, focusing on quantifying waste, identifying potential problems and opportunities for improvement, and timing all steps. Gaining a clear understanding of process performance is crucial for determining the most effective countermeasures to eliminate the root cause of the issue, as well as for planning future actions and determining which KPIs to monitor to improve efficiency.

Lack of vision and knowledge of the same

Many improvement initiatives were implemented, often in isolation, without aiming at a broader, overarching goal. The risk was that the improvement activities, while excellent, were not aligned with any explicit and shared purpose.

Focus on the efficiency of individual phases

The focus was shifted to phase efficiency, leading to difficulties in making the correct process choices.

PLAN

Lean RoadMap® in Deployment

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the SPF Chilò team. The Lean RoadMap® outlines the techniques and methods applied throughout the project

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective. Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it. The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

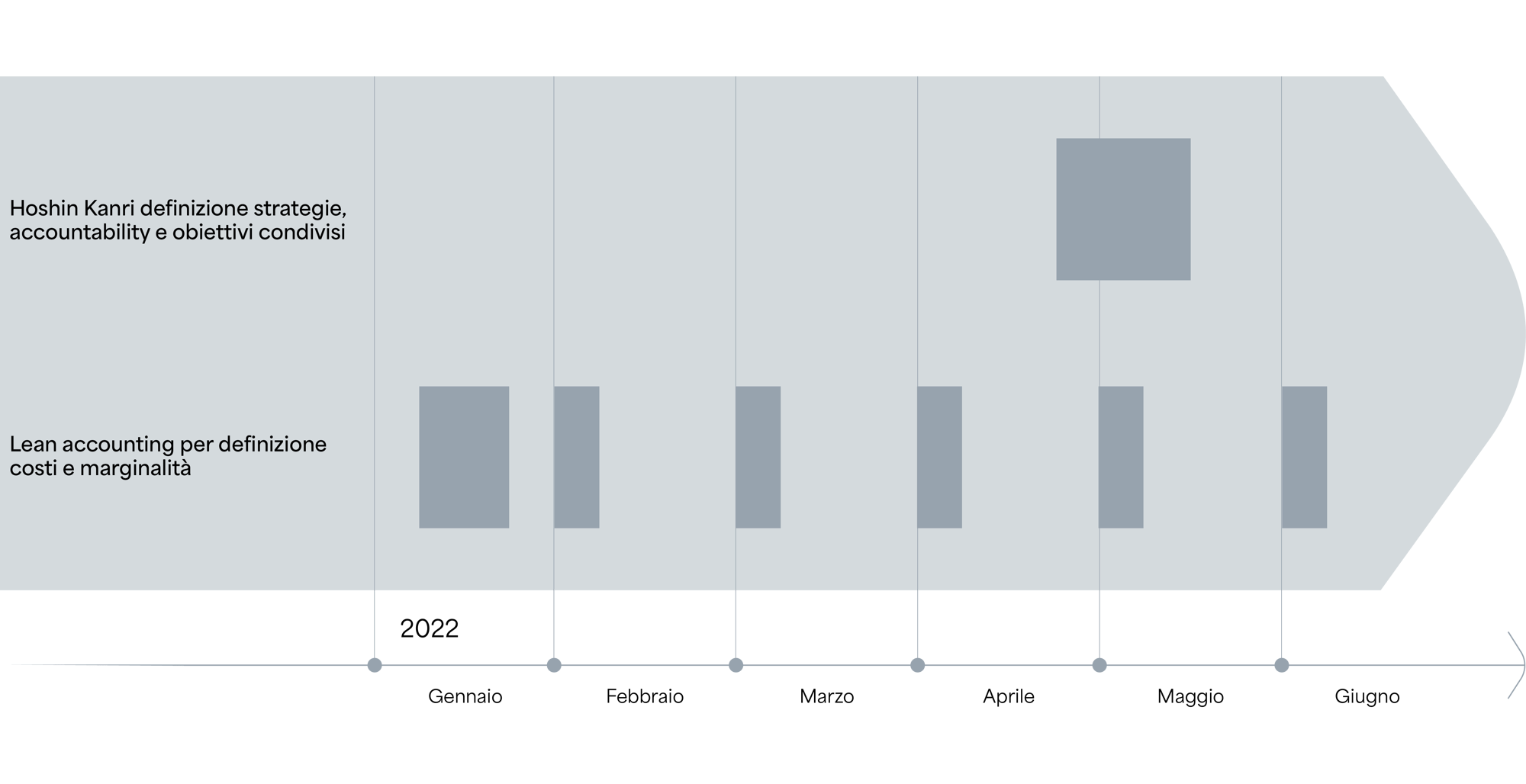

Hoshin Kanri

To define a shared strategy, set the company's True North, and establish short-term objectives.Lean acconting

To provide a management control dashboard, enabling better decision-making for process control and aligning all levels with corporate strategy

DO

Hoshin Kanri

Which lean activities and techniques enabled us to achieve our goal?

Hoshin Kanri

Establishing the True North of the company (interviewing all stakeholders – especially the owners) and sharing everything they had in mind. Brainstorming and then decision making on what was really important. Based on the True North, four to five key strategies were defined, followed by an analysis of the tactics required to achieve them.

Lean accounting

CHECK

Have we achieved our goals?

Strategic team meetings have been scheduled monthly and bi-monthly to review ongoing projects and assess deviations from the projects based on key performance indicators.

Weekly meetings between the ownership and the key management team have been set up to evaluate the progress of projects in line with the established business strategy and to address any deviations.

From Deployment to future opportunities

The project in Deployment was the one that enabled all other projects in the other areas to move forward, now assessed as aligned with the company’s overall strategy.

Our experts are available to support you with process transformation

Subscribe to our newsletter and receive exclusive content, practical tips, and updates delivered directly to your inbox!